A liquid level sensor circuit diagram represents an advanced electronic mechanism for detecting and monitoring liquid volumes in various containers, utilizing innovative sensing technologies that convert physical liquid presence into electrical signals. These sophisticated circuits enable precise measurement across industrial, automotive, agricultural, and consumer applications by transforming liquid interactions into measurable electrical responses.

What Are Liquid Level Sensor Circuit Fundamentals?

Core Components of Liquid Level Sensor Circuits

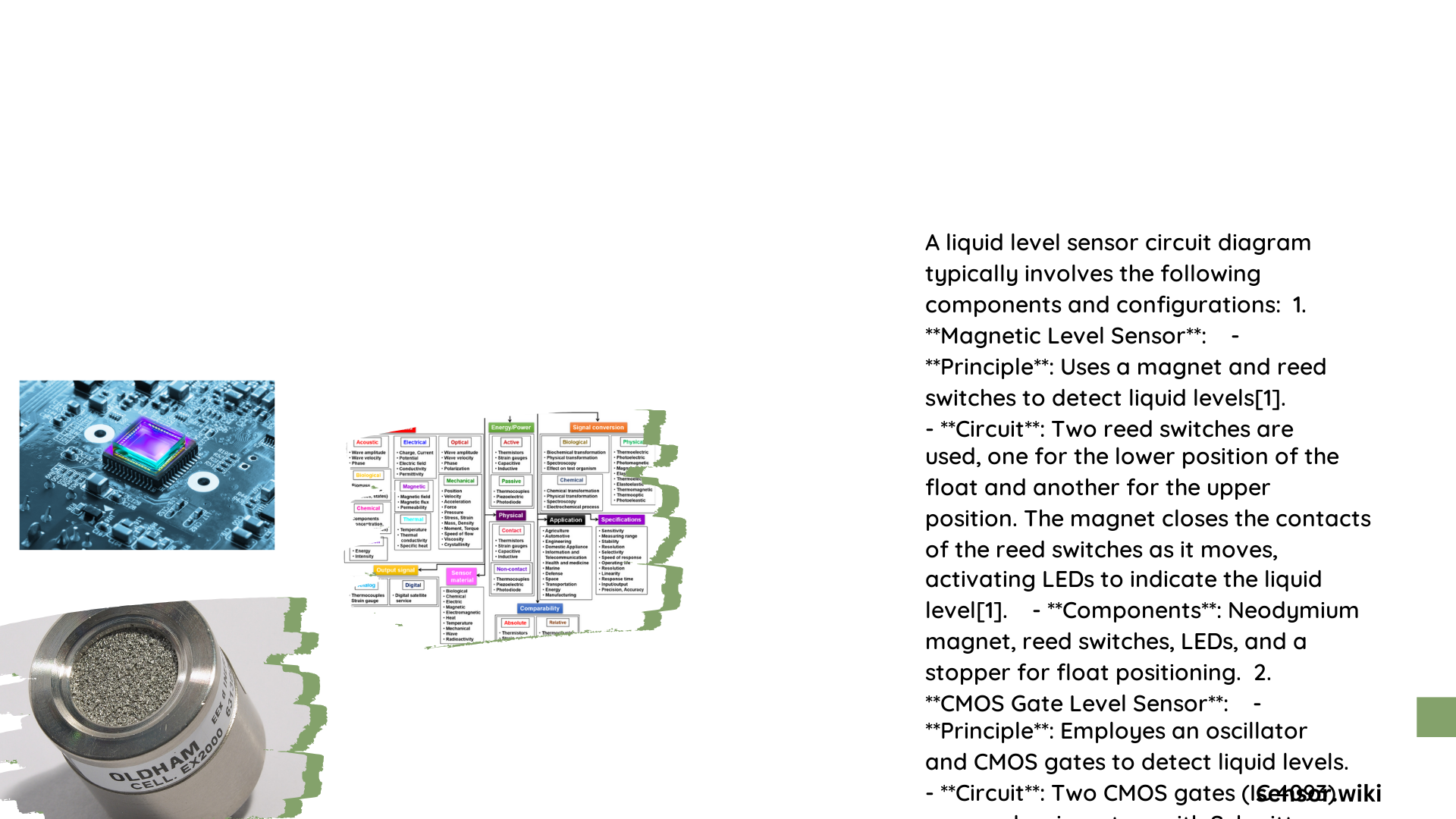

| Sensor Type | Key Components | Detection Mechanism |

|---|---|---|

| Magnetic Float | Reed Switches, Magnet | Mechanical Position Tracking |

| CMOS Gate | Probes, IC 4093 | Electrical Conductivity |

| Optical | Infrared LED, Phototransistor | Light Refraction |

| Capacitive | Sensing Electrode, Signal Processor | Capacitance Change |

How Do Different Liquid Level Sensor Circuits Work?

Magnetic Float Sensor Circuit Design

Technical Specifications:

– Operating Voltage: 5-12V DC

– Sensing Range: Customizable based on float length

– Accuracy: ±1-2% of total range

Circuit Configuration:

– Magnet-embedded float moves vertically

– Reed switches activate at predetermined levels

– LED indicators provide visual liquid level representation

CMOS Gate Liquid Level Detection Circuit

Key Design Elements:

– Oscillator frequency: 10-50 kHz

– Probe material: Corrosion-resistant stainless steel

– Signal processing: Schmitt trigger configuration

Operational Steps:

1. Apply frequency across sensing probes

2. Detect conducting path when liquid contacts probes

3. Trigger relay or microcontroller signal

Optical Liquid Level Sensor Architecture

Sensing Mechanism:

– Infrared LED emits consistent light beam

– Phototransistor monitors light refraction

– Signal processor interprets light intensity changes

Performance Characteristics:

– Response Time: <10 milliseconds

– Temperature Compensation: Built-in algorithms

– Non-contact sensing capability

What Are Critical Design Considerations?

Circuit Design Challenges

- Signal Interference: Minimize electrical noise

- Material Compatibility: Select corrosion-resistant components

- Calibration Complexity: Ensure precise threshold detection

- Environmental Adaptability: Handle temperature and pressure variations

Practical Implementation Guidelines

Component Selection Criteria

- Sensor Type Selection

- Evaluate liquid properties

- Consider environmental conditions

-

Determine required accuracy

-

Power Supply Requirements

- Match voltage specifications

- Ensure stable current supply

-

Implement voltage regulation

-

Signal Processing Techniques

- Use microcontroller for advanced processing

- Implement digital filtering

- Add error correction algorithms

Troubleshooting Common Circuit Issues

- False Readings: Recalibrate sensor thresholds

- Corrosion Problems: Use protective coatings

- Signal Instability: Add noise suppression circuits

- Limited Range: Modify probe configuration

Conclusion

Liquid level sensor circuit diagrams represent sophisticated electronic solutions for precise liquid volume measurement, combining advanced sensing technologies with intelligent signal processing techniques.