Hall sensor rotor position technology represents a critical advancement in precision motor control, enabling accurate and reliable position detection through magnetic field interactions. These sophisticated sensors provide real-time rotor positioning by detecting magnetic field variations, transforming industrial automation, robotics, and electric vehicle propulsion systems with their high-resolution tracking capabilities.

What Makes Hall Sensor Rotor Position Essential?

How Do Hall Sensors Detect Rotor Position?

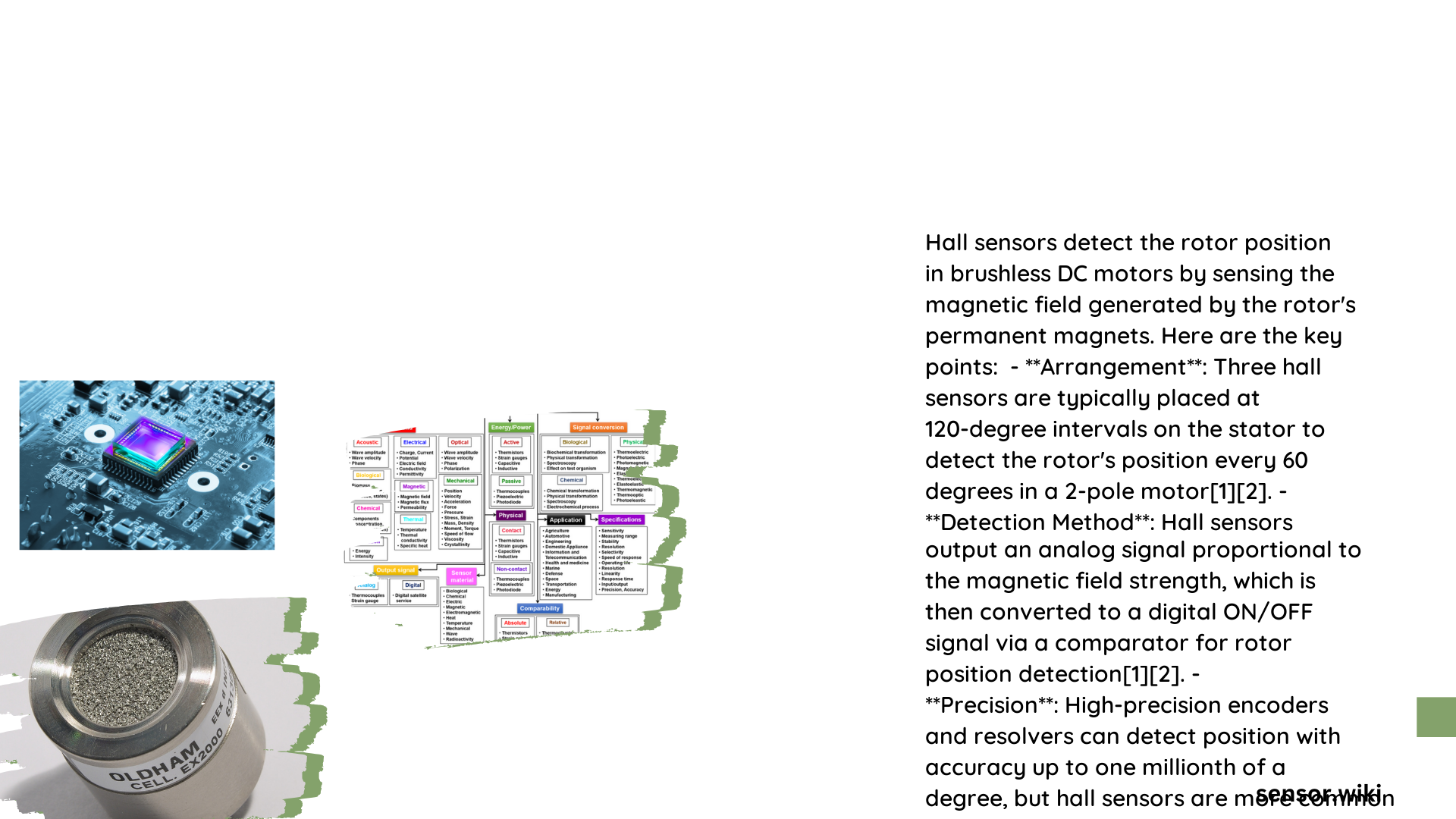

Hall sensors operate on the principle of the Hall effect, where a magnetic field perpendicular to an electrical current generates a voltage difference across the sensor. In rotor position detection, these sensors are strategically placed to monitor magnetic field changes produced by permanent magnets attached to the rotor.

Key Detection Mechanisms

| Detection Method | Characteristic | Precision Level |

|---|---|---|

| Magnetic Field Sensing | Detects magnetic pole transitions | High |

| Voltage Threshold Switching | Triggers at specific magnetic field strengths | Medium-High |

| Angular Position Mapping | Provides precise rotational angle information | Very High |

What Determines Hall Sensor Sensitivity?

Hall sensors exhibit remarkable sensitivity characteristics:

- Magnetic Operating Point (BOP): Typically ranges between 5-20 Gauss

- Magnetic Release Point (BRP): Varies based on sensor design

- Temperature Stability: Maintains performance across -40°C to 150°C ranges

What Are the Resolution Capabilities?

Resolution depends on multiple factors:

- Number of Hall sensors

- Sensor placement angle

- Magnetic pole configuration

- Motor pole count

For a standard 2-pole motor configuration:

– Three Hall sensors provide 120-degree electrical angle coverage

– Enables position detection every 60 electrical degrees

– Allows for precise commutation and speed control

How Are Hall Sensors Calibrated?

Calibration involves several critical steps:

- Aligning sensors with rotor magnetic poles

- Compensating for mechanical and electrical angle variations

- Implementing software-based correction algorithms

- Verifying sensor output consistency

What Challenges Exist in Hall Sensor Rotor Position Detection?

Potential challenges include:

- Magnetic field interference

- Temperature-induced performance variations

- Mechanical misalignment

- Sensor degradation over time

What Industries Benefit from Hall Sensor Rotor Position?

- Electric Vehicle Propulsion

- Industrial Robotics

- HVAC Systems

- Renewable Energy Generators

- Precision Manufacturing Equipment

What Future Developments Are Anticipated?

Emerging trends in hall sensor rotor position technology:

- Increased miniaturization

- Enhanced temperature tolerance

- Higher resolution sensing

- Integration with advanced signal processing algorithms

Practical Implementation Considerations

Sensor Selection Criteria

- Magnetic field sensitivity

- Operating temperature range

- Package dimensions

- Cost-effectiveness

- Reliability metrics

Performance Optimization Strategies

- Implement advanced filtering techniques

- Use redundant sensor configurations

- Develop robust calibration procedures

- Integrate adaptive compensation algorithms

Conclusion

Hall sensor rotor position technology continues to evolve, offering unprecedented precision in motor control and position detection across diverse industrial applications.