AMR magnetoresistive sensors represent a sophisticated magnetic sensing technology that transforms magnetic field variations into precise electrical resistance changes. These advanced sensors leverage anisotropic magneto-resistance principles to detect minute magnetic field alterations with exceptional accuracy, making them critical components in automotive, consumer electronics, industrial automation, and precision measurement applications.

What Are AMR Magnetoresistive Sensors?

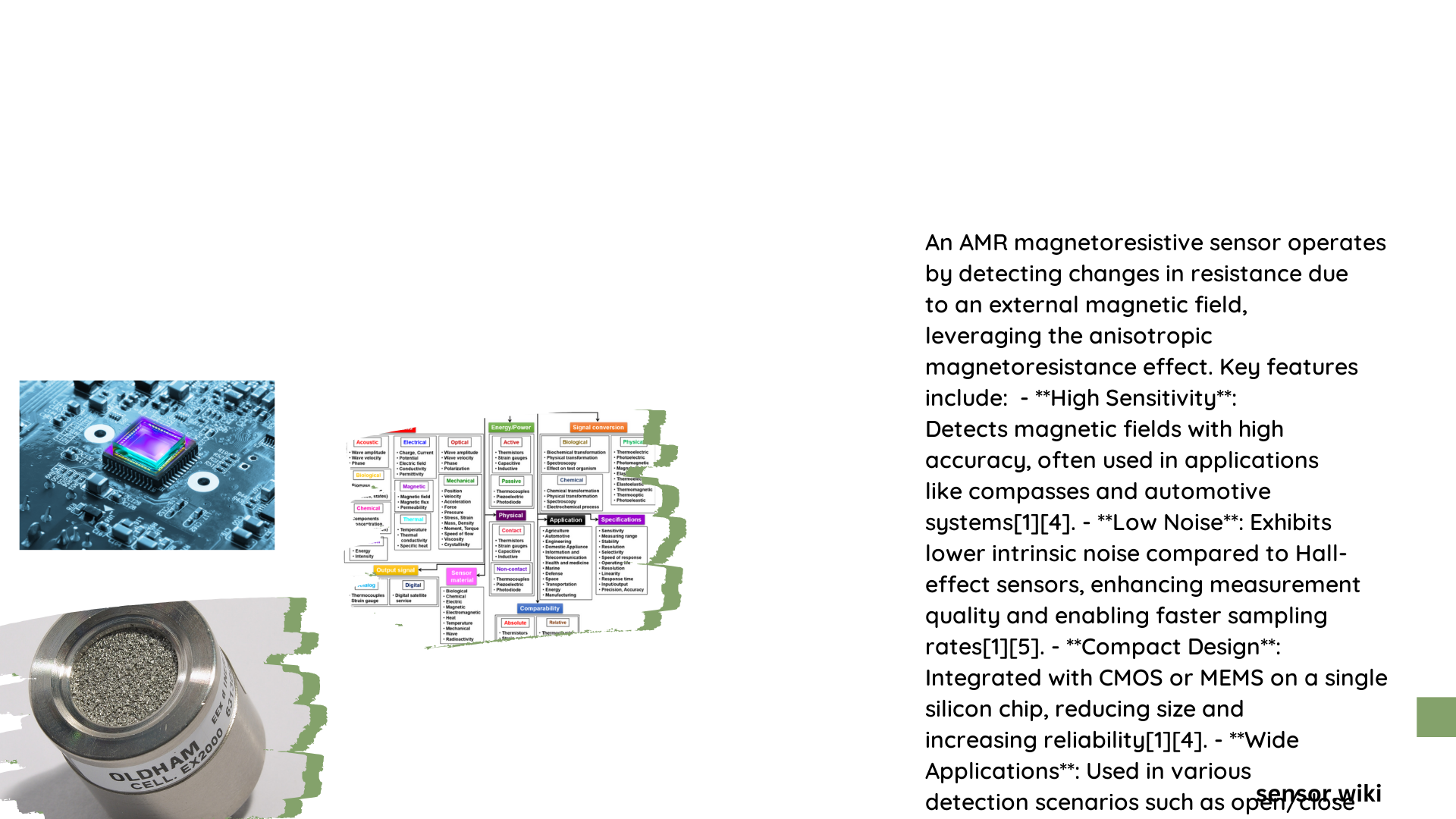

AMR magnetoresistive sensors are specialized electronic devices designed to measure magnetic field strength and direction by exploiting the unique magnetic properties of ferromagnetic materials. Unlike traditional sensing technologies, these sensors provide high-resolution magnetic field detection through resistance modulation.

Core Characteristics of AMR Sensors

| Parameter | Typical Range |

|---|---|

| Sensitivity | 0.1 – 10 mT |

| Operating Temperature | -40°C to 125°C |

| Power Consumption | 2-5 mA |

| Response Time | <1 millisecond |

How Do AMR Magnetoresistive Sensors Work?

Fundamental Principles of Magnetic Field Detection

AMR sensors operate through a sophisticated mechanism where electrical resistance changes proportionally to applied magnetic fields. The primary materials used include:

- Permalloy (Nickel-Iron alloy)

- Specialized ferromagnetic thin films

- Multilayer magnetic structures

Mathematical Representation

The resistance change can be mathematically described by:

[ R = R_0 + \Delta R \cos^2(\theta) ]

Where:

– (R_0): Baseline resistance

– (\Delta R): Resistance variation

– (\theta): Angle between magnetic field and current direction

What Are the Key Applications?

Automotive Industry Applications

- Wheel Speed Sensing

- High-precision rotation detection

- Low-speed performance monitoring

- Enhanced safety systems

Consumer Electronics

- Position and Orientation Sensing

- Smartphone lid detection

- Magnetic switch implementations

- Compact design requirements

Industrial Automation

- Current Measurement

- Non-contact current sensing

- High accuracy measurements

- Low power consumption

What Advantages Do AMR Sensors Offer?

Performance Superiority

- High Sensitivity: Detect magnetic fields as low as 0.1 mT

- Low Noise Characteristics

- Compact Form Factor

- Wide Temperature Tolerance

Comparative Analysis

| Sensor Type | Sensitivity | Power Consumption | Size |

|---|---|---|---|

| AMR Sensor | High | Low | Compact |

| Hall Effect | Moderate | Moderate | Larger |

| Inductive | Low | High | Bulky |

What Technical Challenges Exist?

Potential Limitations

- Temperature-induced sensitivity variations

- Complex calibration requirements

- Material-specific performance constraints

Future Development Trajectories

Emerging Research Areas

- Nano-structured magnetic materials

- Enhanced signal processing algorithms

- Integration with artificial intelligence

- Miniaturization of sensing technologies

Conclusion

AMR magnetoresistive sensors continue to revolutionize magnetic field detection across multiple technological domains, offering unprecedented precision, efficiency, and reliability.

Expert Recommendations

- Prioritize sensor calibration

- Consider environmental operating conditions

- Evaluate specific application requirements

References:

– Murata Sensor Technology

– Texas Instruments Sensor Resources

– ACEINNA Sensor Solutions