Flex sensors are innovative devices that measure the amount of deflection or bending. These thin, flexible strips change their resistance when bent, allowing for precise measurement of angular displacement. Widely used in robotics, wearable technology, and various electronic applications, flex sensors have revolutionized motion sensing and human-computer interaction. This comprehensive guide delves into the intricacies of flex sensors, their specifications, applications, and challenges.

What are the Key Specifications of Flex Sensors?

Flex sensors are characterized by several important specifications that determine their performance and suitability for different applications:

How Does the Resistance Range Vary?

The resistance of a flex sensor changes with the bend angle:

- Unflexed sensor: Nominal resistance typically ranges from 10 KΩ to 25 KΩ

- Bent sensor: Resistance can range from 30 KΩ to 125 KΩ, depending on the bend radius

- Example: A 4.5-inch flex sensor can have a resistance range of 30 KΩ to 40 KΩ when bent at 90 degrees

What is the Sensitivity of Flex Sensors?

Sensitivity is a crucial aspect of flex sensors:

- Measured through voltage change using a voltage divider circuit

- Output voltage (Vo) changes linearly with the bend angle

- Allows conversion of resistance changes to voltage changes

- Sensitivity can be adjusted using a voltage divider circuit or an operational amplifier

What are the Physical Dimensions of Flex Sensors?

Flex sensors come in various sizes to suit different applications:

| Dimension | Common Sizes |

|---|---|

| Length | 2.2 inches (55.37 mm), 4.5 inches (114.3 mm) |

| Width | 0.25 inches (6.35 mm) to 0.25 inches (6.41 mm) |

| Thickness | 0.017 inches (0.43 mm) to 0.019 inches (0.48 mm) |

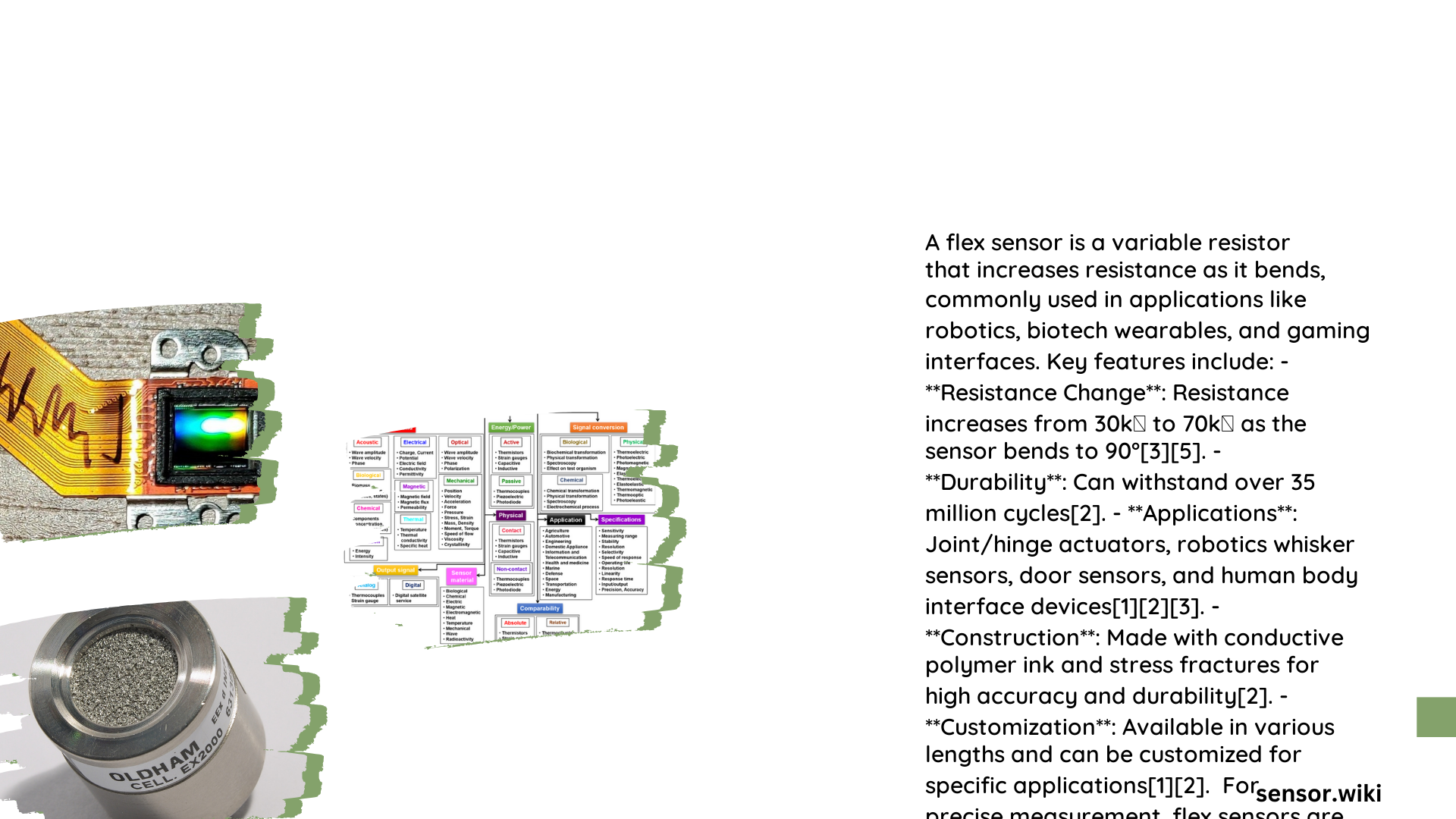

What are the Different Types of Flex Sensors?

Flex sensors are categorized based on their resistance types:

- LOW resistance

- MEDIUM resistance

- HIGH resistance

They are also distinguished by their size and the material used, such as conductive polymer.

Where are Flex Sensors Applied?

Flex sensors find applications in various fields:

- Robotics: Used for collision detection and motion sensing in mobile robots

- Wearable Technology: Utilized in sign language translation gloves, VR gloves, and VR suits

- Medical Devices: Employed for measuring heartbeats and other medical applications

- Gaming: Used in virtual motion and gaming interfaces, such as the Nintendo PowerGlove

- Computer Peripherals: Applied in various computer peripherals and musical instruments

What Challenges Do Flex Sensors Face?

Despite their versatility, flex sensors face some challenges:

- Durability: Susceptible to damage, especially at the base where pins are connected

- Solution: Strain relief is necessary to ensure longevity

- Temperature Sensitivity: Operating temperature range typically -35°C to +80°C

- Impact: Can affect the sensor’s accuracy and lifespan

How Much Do Flex Sensors Cost?

The cost of flex sensors varies based on manufacturer and specifications:

- Single 4.5-inch flex sensor: Approximately $10 plus shipping and handling

- Bulk purchases can reduce cost per unit:

- 2.2-inch flex sensor from Adafruit:

- Single unit: $7.95

- 10-99 units: $7.16 each

- 100+ units: $6.36 each

What are the Typical Lead Times for Flex Sensors?

Lead times can vary depending on the supplier and buyer location:

- Orders from online retailers like Adafruit or SparkFun: Usually shipped within a few days to a week

How Do Environmental Conditions Affect Flex Sensor Performance?

Environmental factors play a crucial role in flex sensor performance:

What is the Optimal Temperature Range?

- Operating temperature range: -35°C to +80°C

- Operating outside this range can affect accuracy and lifespan

How Does Humidity Impact Flex Sensors?

- Specific humidity tolerance is not widely documented

- Recommendation: Use in environments with moderate humidity to avoid potential degradation

What is the Expected Lifespan of a Flex Sensor?

- Typical lifespan: Over 1 million cycles

- Assumption: Proper use and strain relief measures are taken

How to Integrate Flex Sensors in Projects?

Integrating flex sensors into projects requires careful consideration:

- Choose the appropriate sensor size and resistance range for your application

- Design a voltage divider circuit or use an operational amplifier for signal conditioning

- Implement strain relief measures to protect the sensor base and increase longevity

- Calibrate the sensor for your specific use case to ensure accurate measurements

- Consider environmental factors such as temperature and humidity in your design

By understanding these key aspects of flex sensors, engineers and hobbyists can effectively incorporate this versatile technology into their projects, pushing the boundaries of motion sensing and human-computer interaction.

References:

1. Flex Sensor – University of Alberta

2. Flex Sensor Features, Working, Circuit & Datasheet – Components101

3. FLEX SENSOR DATA SHEET – SparkFun